790050_DOUBLE EFFECT PNEUMATIC ACTUATOR_INOX

DOUBLE EFFECT PNEUMATIC ACTUATOR IN ALUMINIUM NICKEL – 90°

•Forged Stainless Steel type A182 – F316 – EN 10088/3 – 1.4401 Body, inside surface finish (Ra 0,4 – 0,6 um) to minimize friction and maximize the actuator’s life.

•ENAB 46100 T6 die-casted Aluminium alloy Pistons, Anodizing.

•Micro-casted Stainless Steel type A182 – F316 – EN 10088/3 – 1.4401 Covers.

•Forged Stainless Steel type AISI 316 (A4) Shaft.

•Screws in Stainless Steel AISI 316 (A4).

•Seals in nitrile nubber NBR.

•Acetalic resin + 20% PTFE Bearings, made by low friction coefficient material to avoid “metal to metal” contact, easely replaceable for maintenance.

•High performances Syntetic Grease.

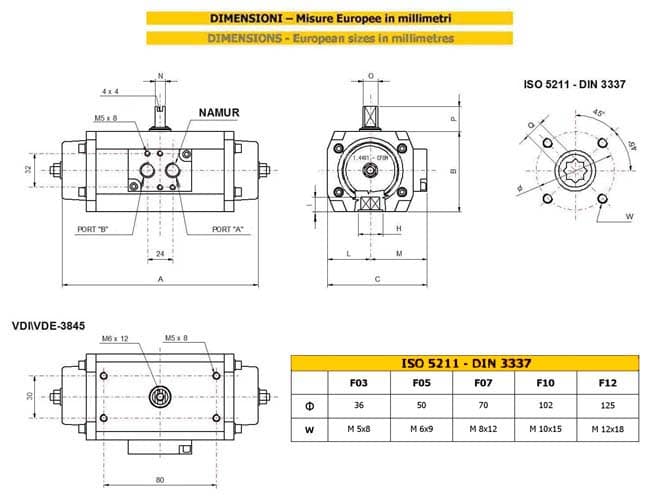

•Double lower drilling for valve fastening and centering according to ISO 5211-DIN 3337 standards.

•Lower female shaft key according to ISO 5211-DIN 3337 standards to assembly on valves with square key on line and 45° shaft.

•Solenoid connections according to NAMUR VDIVDE-3845 standards.

•Top drilling for accessories fastening, and upper shaft end according to NAMUR VDIVDE-3845 standards.

•3D position indicator.

•Adhesive nameplates with progressive serial number punched.

•The lubrification carried out by the manufacturer is guaranted for min. 1.000.000 operations.

•Running test and 100% seal test carried out with electronic equipment and certification of each individual product.

•According to ATEX 2014/34/UE Standard for explosive environnement; STANDARD version actuator: I M2 – II 2GD c Tmax = 95°C.

•According to EN 15714-3 design and manufacture standard requirements.

•EN 60529\A1 – Protection degree of casings IP 67.

USE:

AIR SUPPLY: dry or lubricated filtered compressed air.

TEMPERATURE RANGE: -20°+80°C

FEEDING PRESSURE: 1 bar minimum – 8 bar/120 psi maximum.

STANDARD ROTATION: counterclockwise.

| TYPE | 3 BAR | 4 BAR | 5 BAR | 6 BAR | 7 BAR | 8 BAR | CODE |

|---|---|---|---|---|---|---|---|

| AP 032-I | - | 5 | 6,3 | 7,6 | 8,8 | 10 | 790050 6050A |

| AP 042-I | 6,5 | 8,7 | 10,9 | 13,0 | 15,2 | 17,3 | 790050 6070A 3D |

| AP 050-I | 9,2 | 12,3 | 15,4 | 18,5 | 21,5 | 24,6 | 790050 6100A 3D |

| AP 063-I | 16,5 | 22,0 | 27,5 | 33,0 | 38,5 | 44,0 | 790050 6160A 3D |

| AP 075-I | 35,1 | 46,8 | 58,5 | 70,2 | 81,9 | 93,6 | 790050 6200A 3D |

| AP 085-I | 53,4 | 71,2 | 89,0 | 107 | 125 | 142 | 790050 6250A 3D |

| AP 100-I | 83,2 | 111 | 139 | 166 | 194 | 222 | 790050 6300A 3D |

| AP 115-I | 137 | 183 | 229 | 275 | 320 | 366 | 790050 6350A 3D |

| AP 125-I | 181 | 241 | 301 | 361 | 421 | 481 | 790050 6400A 3D |

| AP 145-I | 260 | 347 | 433,5 | 520 | 607 | 694 | 790050 6450A |

ACTUATOR TORQUE IN Nm

| POSITION | AP 042 | AP 050 | AP 063 | AP 075 | AP 085 | AP 100 | AP 115 | AP 125 |

|---|---|---|---|---|---|---|---|---|

| A-90° | 140 | 139 | 152 | 205 | 230 | 275 | 307 | 359 |

| B | 57 | 67 | 83 | 100 | 110 | 125 | 142 | 155 |

| C | 71 | 79 | 103 | 118 | 128 | 145 | 166 | 178 |

| L | 30,5 | 41,5 | 41,5 | 49 | 54 | 62.5 | 73 | 79 |

| M | 40,5 | 51,5 | 61,5 | 69 | 74 | 82,5 | 93 | 99 |

| Port.A-Port.B NAMUR | 1/8" GAS | 1/8" GAS | 1/4" GAS | 1/4" GAS | 1/4" GAS | 1/4" GAS | 1/4" GAS | 1/4" GAS |

| N x O | 8 x 12 | 8 x 12 | 8 x 12 | 14 x 18 | 14 x 18 | 14 x 18 | 27 x 36 | 27 x 36 |

| P | 20 | 20 | 20 | 20 | 20 | 20 | 30 | 30 |

| Q x I | 11 x 13 | 11 x 13 | 14 x 16 | 17 x 20 | 17 x 20 | 22 x 25 | 22 x 25 | 27 x 30 |

| F.ISO 5211 | F03 / 05 | F03 / 05 | F03 / 05 | F05 / 07 | F05 / 07 | F07 / 10 | F07 / 10 | F07 / 10 |

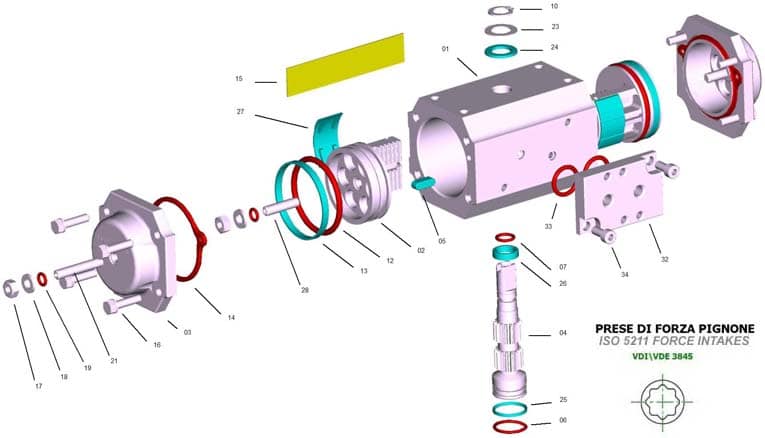

| POS. | DENOMINATION | PCS | MAT. |

|---|---|---|---|

| 1 | Body | 1 | AISI 316 (A4) |

| 2 | Pistons | 2 | ENAB 46100 T6 |

| 3 | Cover | 2 | AISI 316 (A4) |

| 4 | Pinion | 1 | AISI 316 (A4) |

| 5 * | Anti-ejection key | 2 | Resina Acetalica - Acetalic resin |

| 6 * | Pinion inferior O-Ring | 1 | NBR |

| 7 * | Pinion superior O-Ring | 1 | NBR |

| 10 * | Seeger | 1 | Acciaio per molle - Spring steel |

| 12 * | Piston O-Ring | 2 | NBR |

| 13 * | Piston anti-friction ring | 2 | Resina Acetalica - Acetalic resin |

| 14 * | Cover Seal | 2 | NBR |

| 15 | Identification plate | 1 | Alluminio - Aluminium |

| 16 | Cover fixing screw | 8 | AISI 316 (A4) |

| 17 | Nut | 2 | AISI 316 (A4) |

| 18 | Washer | 2 | AISI 316 (A4) |

| 19 * | O-ring | 2 | NBR |

| 21 | Cover screw | 2 | AISI 316 (A4) |

| 23 * | Pinion thrust washer | 1 | AISI 316 (A4) |

| 24 * | Anti-friction washer | 1 | Resina Acetalica - Acetalic resin |

| 25 * | Inferior pinion guide ring | 1 | Resina Acetalica - Acetalic resin |

| 26 * | Superior pinion guide ring | 1 | Resina Acetalica - Acetalic resin |

| 27 * | Piston bearing | 2 | Resina Acetalica - Acetalic resin |

| 28 | Piston Adjusting Screw | 2 | AISI 316 (A4) |

| 32 | NAMUR plate | 1 | AISI 316 (A4) |

| 33 | O-Ring for NAMUR plate | 2 | Resina Acetalica - Acetalic resin |

| 34 | NAMUR plate screw | 2 | AISI 316 (A4) |

| * | Spares kit |